Product Description

Our automatic poultry feeding equipment is assembled by below parts:1. Main feeding line system

2. Broiler pan feeding line system

3. Nipple drinking line system

4. Ventilation& environment control system

5. Heating system

1. Main feeding line system In the main feeding line system the feed is transferred from the silo to the hopper in chicken house by auger. There is a feed sensor at the end of the main feed line which control of open and close of the motor to realize the automatic feeding.

Silo Model |

Volume |

Number of Layers |

Height (exclusive of foundation) |

Material |

| QDSHS-01 |

4.4 m3, 2.8T |

1 |

4.1 m |

Galvanized sheet |

| QDSHS-02 |

6.8 m3, 4.4T |

2 |

5 m |

Galvanized sheet |

| QDSHS-03 |

9.2 m3, 5.9T |

3 |

5.9 m |

Galvanized sheet |

| QDSHS-04 |

11.7 m3, 7T |

1 |

4.7 m |

Galvanized sheet |

| QDSHS-05 |

16.9 m3, 10T |

2 |

5.6 m |

Galvanized sheet |

| QDSHS-06 |

22.1 m3, 13T |

3 |

6.5 m |

Galvanized sheet |

| QDSHS-07 |

24.5 m3, 16T |

1 |

5.8 m |

Galvanized sheet |

| QDSHS-08 |

34 m3, 22T |

2 |

6.7 m |

Galvanized sheet |

| QDSHS-09 |

43 m3, 28T |

3 |

7.6 m |

Galvanized sheet |

Material description:

1. Silo roof plate and silo wall plate layer-galvanized sheets with the thickness of 1.2mm, second layer of silo wall plate-galvanized sheet with the thickness of 1.5mm.

2. Conical bottom plate-galvanized sheet with the thickness of 1.5mm, silo column- hot dip galvanizing on the surface: No. 10 channel steel, support-φ 3.6mm, 8 supports/silo. |

In the pan feeding system the feed sensor control the motor to open and close to realize the automatic feeding. The system consists of hopper, motor, feed pipe and auger.

Name |

Description |

| Pan feeder |

1. By sliding shutter can adjust feed amount from complete open to complete close.

2. Pan plate can be disassembled on the ground working as chick feed pan for 0-7 days old chicken.

3. V-pan plate design can reduce feed storage at pan bottom. Bird can have fresh feed every day. This design can also prevent bird from staying on the plate too long.

4. Motor: power 0.75KW voltage:380V. |

| Hopper |

Capacity: 100L, raw material is hot galvanized steel, coat 120g/ m2 |

| Auger |

Imported from South Africa, feed capacity is 450kg/h. |

| Delivery pipe |

4 pans/3m, diameter: ø45mm |

In modern poultry production, nipple drinkers have proven to be a reliable and hygienic solution for the supply of water. It is consisted by water front parts, drinking system, hanging system, regulator and water line end parts .

Name |

Description |

| Nipple shell |

Made of high-quality engineering plastic, and the valve rod inside is made of high-quality stainless steel. |

| Valve stem |

Can rotate freely at 360 degree to meet bird water demand of different period |

| Hanging system |

It is easy to adjust the height and the levelness by the winch and the adjustable strip |

| Structure |

Double-decked seal structure can effectively avoid wasting water and the resulting impact on the environment humidity. |

| Feeding capacity |

broiler: 8-12 birds /nipple, birds in cage: 12 birds/nipple, breeder: 10 birds/nipple |

| Dosing device |

Flow rate: 10 L / h - 2.5 m3/h

Working pressure :0.3bar-6bar

Dosing rate: 0.02L / h - 50 L/ h

Maximum working temperature: 40ºC

Adjustment ratio: 0.2% to 2%(1:500-1:50)

Connecting size: external thread G3/4 |

Water Level Display Height:

Chicken Age (days) |

1-7days |

8-14days |

More than 15 days |

| Water Level Height of display Tube (mm) |

50-80mm |

80-200mm |

200-350mm |

4. Ventilation& environment control system

4. Ventilation& environment control systema. This system is of great importance for a chicken house, which is used for providing a most suitable growing environment for chicken.

b. The system consists of below parts: air inlet, exhaust fan, cooling pad, spraying system and panel door.

c. Cooling pad and exhaust fan combination is the most economical and effective method to lower the temperature in summer.

Exhaust fan component list:

Name |

Feature |

| Motor |

High efficiency and low wastage of energy. The Grade of protection is IP54 and the Insulation Grade is F. Rated power: 1.1kw, rated voltage: 380v |

| Frame |

Galvanized steel sheet, steel thcikness 275g/m2,stamping forming, bottom outlet. |

| Blade |

Stainless steel blade, By dynamic balance test machine, stable running and volume stability. |

| Shutters |

Hot galvanized sheet forming, with automatic opening device |

| Defend net |

Hot galvanized anti-rust processing. |

| Automatic opening device |

Nylon and glass fiber materials, long life service. |

| Belt |

Imported from Japan, long-term use without deformation. |

| Belt pulley |

Hard alloy material quality by hot die casting, light material and high intensity. |

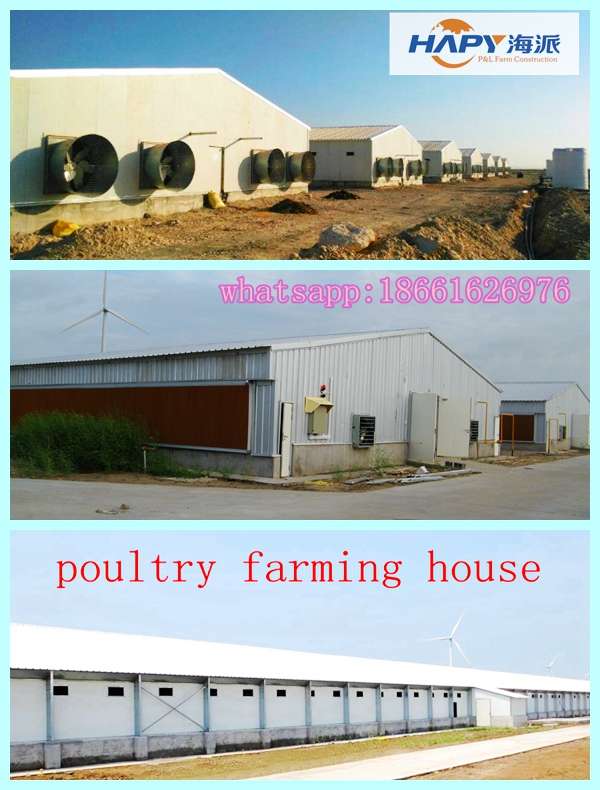

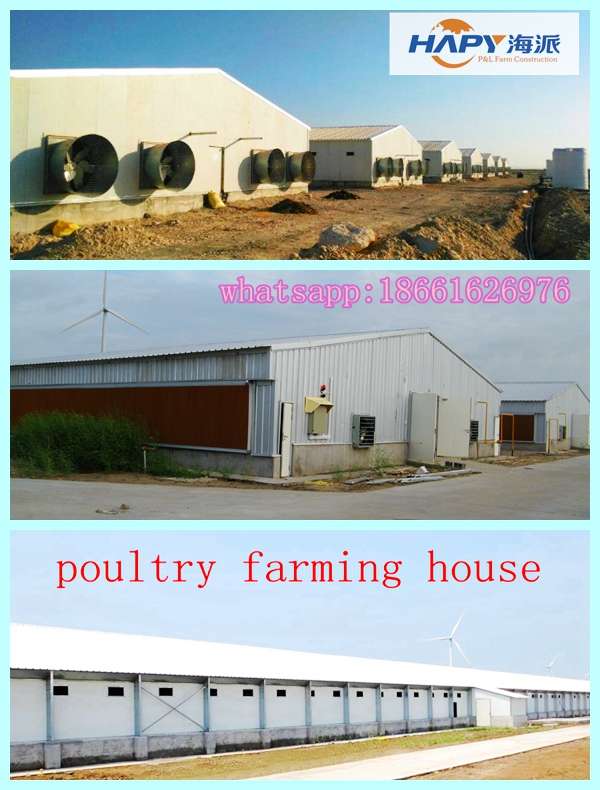

Steel Structure Poultry House:

Steel Structure Poultry House:Features:

Single/ double story poultry house

Anti-corrosive aluminum-zinc coated colored panel

Hot galvanized steel column as structural material

Fiber glass batt for heat preservation

Wide span: single span or multiple spans, the max span is 36m without middle column.

3-6° ceiling pitch, easy for horizontal ventilation.

Service life up to 30~50 years.

Roof pitch 10°~15°(decided by local climate)

The project construction period is shorter than the brick structure project. For example:12 workers can assemble 1000sqm within 20 days.

Advantages:

Advantages:Galvanized framework and aluminum-zinc coated sheet ensures the long service life of the concreted houses.

Optimal truss design for lightweight steel construction, cost saving.

Fine quality fiber glass butt for nice heat preservation and plastic film for excellent humidity insulation.

Nice frame connection design, beautiful in appearance and stable in performance.

Optimized corner trimming ensures the nice sealing effect.

Considering all the pre-embedded parts needed for equipment installation or suspension in advance, ensures convenient and solid installation.

Each construction material is verified by Hapy through various projects construction experience. We ensures that all the materials match the entire design of the project.

The houses finished by Hapy are perfectly matched with the equipment going to be mounted, which guarantees the best equipment performance.

Low cost: unit price range from USD 30/m2 to USD 60/m2 according to customers request.

environmental protection, stable structure, earthquake resistance, water proofing, and energy conserving, steel structure recoverable.

Construction Period For Typical Poultry Farm Project (take six 18m*150m standard poultry houses project as an example)

| |

Construction time |

Equipment installation time |

Total Time |

| Steel structure poultry house |

45 days |

30 days |

75days |

Concrete structure poultry house

|

100days |

30days |

130days |

Certificate

Quality certification ISO: 9001: 2008;

SGS Inspection and other third party Inspection acception.

Quality& service

Full and advanced equipment: CNC laser cutting machine; CNC bending machines;

Nc drilling machine CNC Continuous mode of production lines etc.

Strictly quality control: Inspection every link; Pre assembled before delivery.

FAQ:

What information is required to get a suitable quotation? |

| a. Chicken farm size (Length*width*height) |

| b. Quantity of chickens in one farm |

| c. Types of chicken: broiler, breeder or layer |

| d. Types of breeding: floor or cage |

| e. Chicken farm location and local climate condition (temperature, humidity...) |

| f. More information you think helpful |

1. Poultry House site Selection

2. Poultry House Design and Construction Preparation Guidance.

3. poultry house construction

4. Breeding Equipment producing and Installation

5.After-sale Services

Our factory :

Our factory :1. Professional steel structure manufacturers since 2003.

2. Professional poultry equipment manufacturers since 2009

3. 2, 0000 sqare meters workshop for steel structure

We have lots of construction projects home and abroad, our sales volume in Philippine market is NO.1, we are the best and the most reliable supplier in this area, and also we are the top 3 supplier in Pakistan and Sudan.

Also, our company is recruiting global agents, welcome you to join us with our utmost and warm expectation.

So if you are interested in our product, please feel free to contact us, it will be our big pleasure if we have opportunities to be on service of you in the near future.

Company Profile

Company Profile